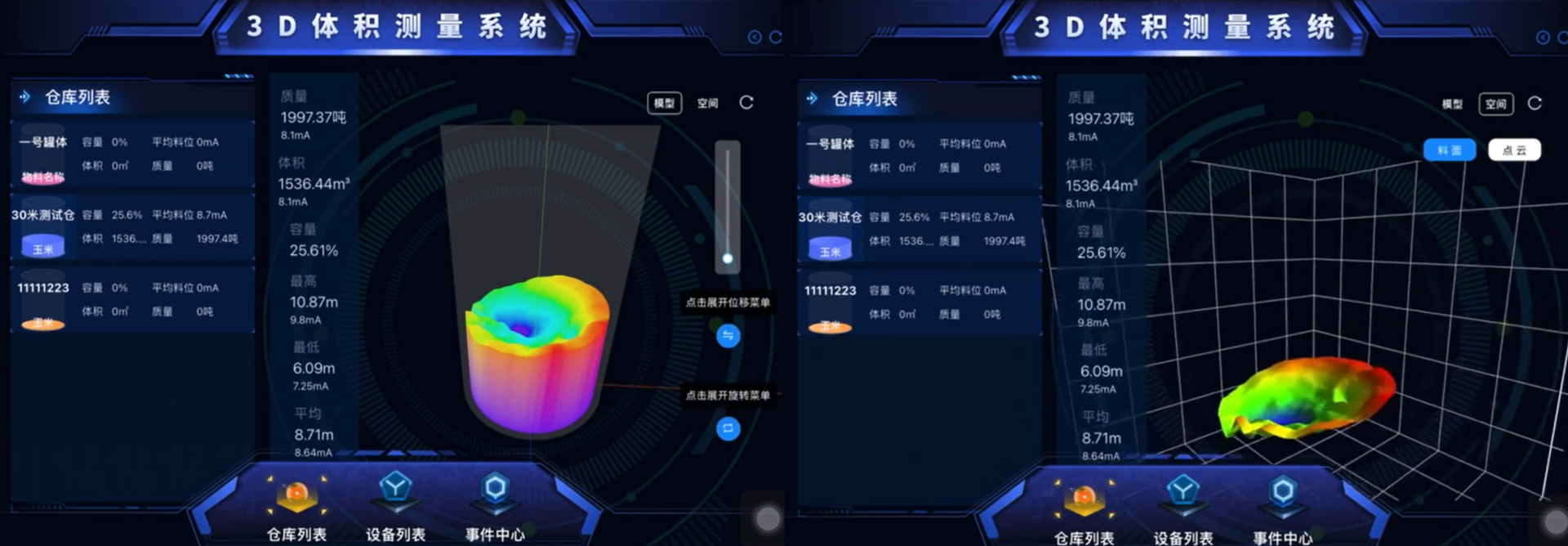

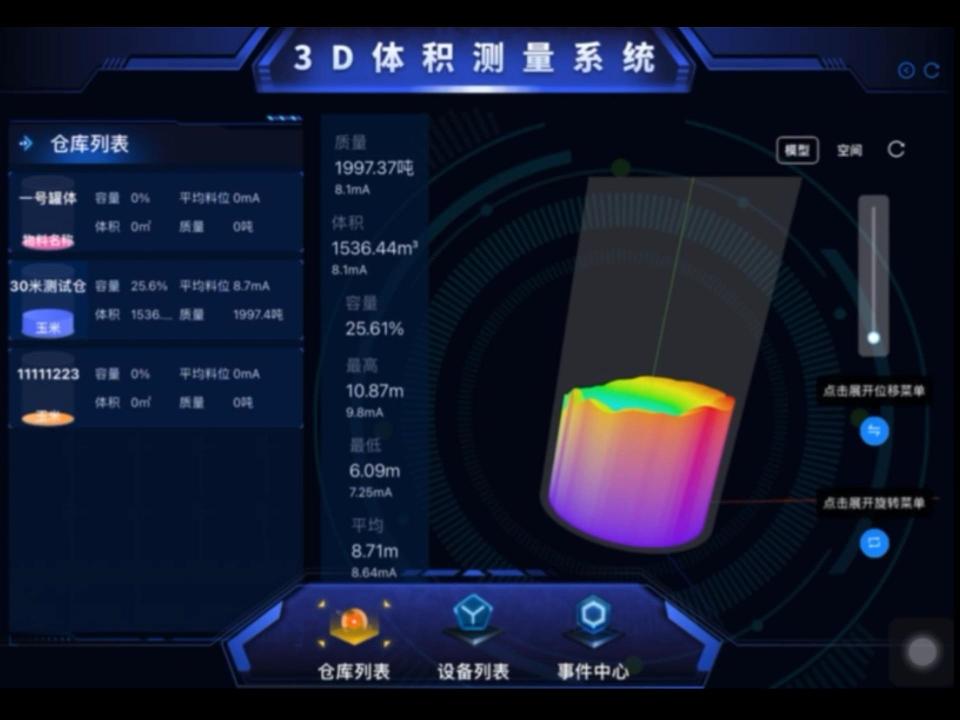

3D millimeter wave volume measurement system

Description

To obtain accurate inventory levels and meet the needs of data and information management in large enterprises, reliable and fast volume detection has become particularly important. Our company's independently developed high-frequency millimeter wave radar volume detection system is based on high-precision millimeter wave radar to scan material piles. Through large field of view detection, high-density point clouds are generated. At the same time, the built-in algorithm directly outputs volume measurement values, which can be used for 3D reconstruction, material level, coal pile, grain silo and other target volume detection. Internally integrated millimeter wave radar with different ranges, up to a maximum range of 180m, to meet the ranging needs of different customers.

1. Widely used in material transportation and molten iron position measurement and control in processes such as coking, ironmaking, and steelmaking

2. Used for cement clinker storage, cement finished product storage, building materials storage and raw material storage, adopting multi-point surface scanning to more comprehensively understand the material information inside the cabin.

3. Used for monitoring the material level of ash and limestone silos, guiding coal co firing, and achieving automated transformation of incoming and outgoing materials.

4. It can be used for measuring and monitoring coal bunkers and coal sheds, realizing digital coal bunkers. Through visualization, it can accurately guide the material distribution and retrieval of the entire coal bunker.

5. Applied to intelligent systems for grain raw material silos, clay tanks, soybean skin warehouses, soybean meal warehouses, and various warehousing projects.

1. Model: SW-RDV20X Ex;

2. Range: 180m;

3. Radar type: millimeter wave radar;

4. Radar system: phased array radar;

5. Operating frequency: 70GHz~80GHz;

6. Horizontal scanning angle: 0~360 °;

7. Pitch scanning angle: -90 °~90 °;

8. Horizontal step angle: 1 ° (adjustable);

9. Pitch step angle: 1 ° (adjustable);

10. Single cycle scanning modeling time: 90 seconds (adjustable);

11. Number of point clouds scanned in a single cycle: 20000 (adjustable);

12. Volume measurement accuracy: ≤ 1%;

13. Level measurement accuracy: ± 2mm;

14. 3D modeling: ± 1% FS~± 2% FS;

15. Power supply voltage: 24V DC;

16. Maximum power: ≤ 25W;

17. Communication methods: fiber optic, 4G/5G, Ethernet;

18. Equipment weight: 3KG;

19. Operating temperature: -40 ° C~80 ° C;

20. Environmental temperature: -40 ° C~85 ° C;

21. Working pressure: 0~1 bar;

22. Protection level: IP67;

23. Explosion proof grade: Ex ta IIIC 200 85 ℃ Da;

02 Commit